Kloboucká lesní s.r.o.

Vlárská 321

763 31 Brumov-Bylnice

T +420 577 320 134

M info@klobouckalesni.cz

10

10

Kloboucká lesní s.r.o.

Vlárská 321

763 31 Brumov-Bylnice

T +420 577 320 134

M info@klobouckalesni.cz

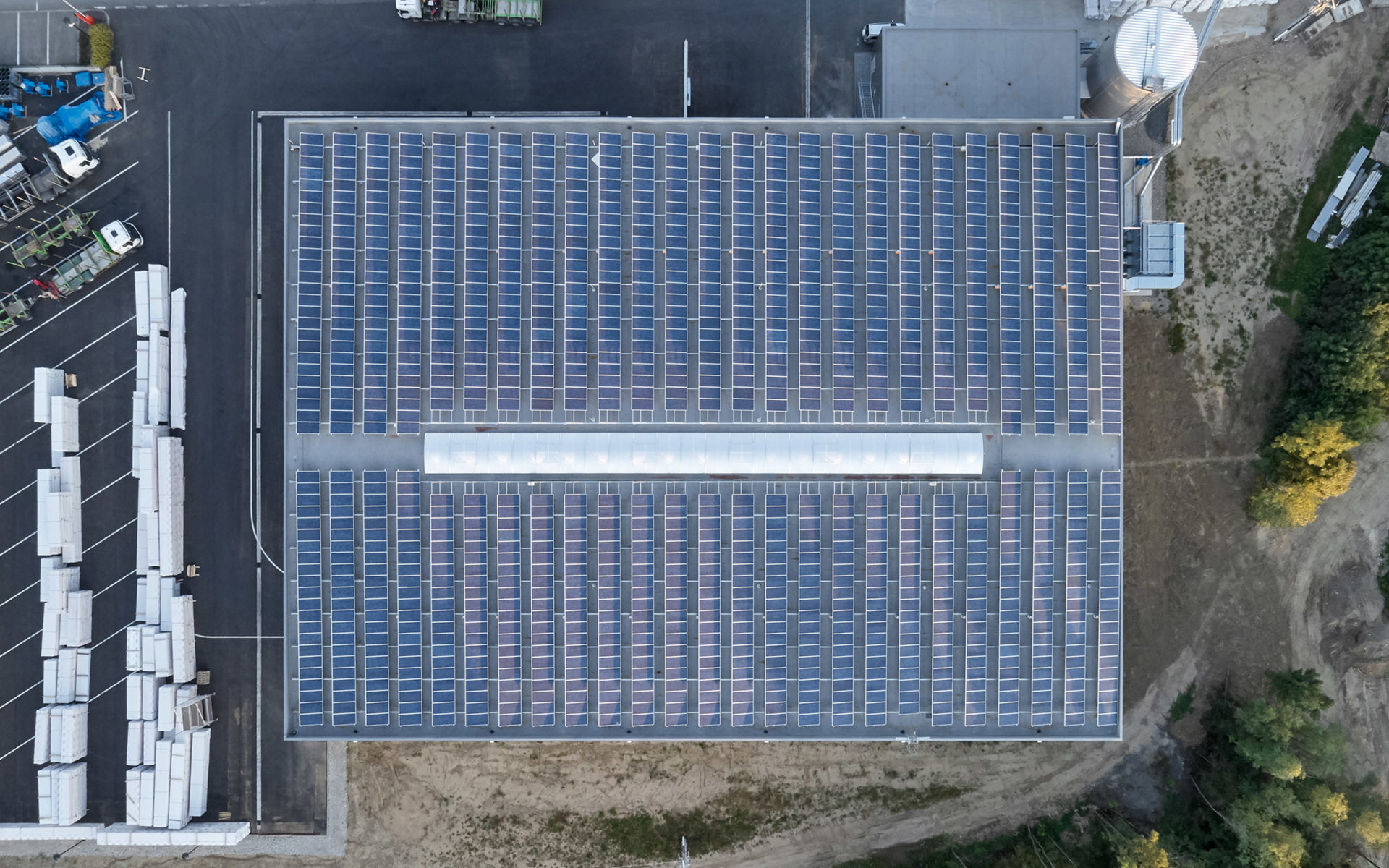

A building that lets the light in. Massive wooden beams reminding us we are not in just any ordinary factory. A smart ceiling system which hides automatic fire extinguishers, energy-efficient LED lighting, and a siphonic rainwater drainage system.

The 3,975 m2 hall for the production of glulam beams was designed to allow the wood and people to breathe easily here. Every month, we reshape up to 2,000 m3 of wood into glulam beams on our German machinery and turn the scrap into pellets, ensuring virtually zero waste.

Spruce, Douglas fir, and even larch await a meticulous process of sorting, cutting, gluing, and planing. To make sure the wood meets our strict quality standards, we let it acclimatize for a day and carefully monitor its moisture levels. There is no room for error when gluing beams that adhere to the C24S10 norm.

DID YOU KNOW...?

In modern construction, wood is able to compete with concrete and steel. Advancements in gluing technologies allow it to match these other materials in statics as well as fire protection criteria. Not only that, wood is sustainable and, most importantly, it smells amazing.

Large knots, splits, cracks – none of these have a place in our beams. Beyond being functional, they must also be gorgeous to look at. Only premium-grade S10 and S7 wood makes it to the next step of the process.

We check the moisture levels again. Cut the wood to the right length. Mill the finger joints. Add the glue. Join into one piece. All this mechanical precision leads to one goal: strong boards with a length ranging from 4 to 13.6 m, the building blocks of future beams.

Two paths lead to the final goal of quality beams ranging in width from 80 to 300 mm: SST and BSH. The SST route is shorter. It goes from the stacker machine over to the four-sided planer, then to the mitre saw to be cut, after which a completed beam slides out.

BSH beams need more time. After planing, the lamellas travel along a belt to the forming line, where we decide which one will go on the outer side of the beam and which will stay inside. This lets us guarantee that every beam is beautiful, especially since each one will decorate the interiors of households and companies. Then we apply the glue and start pressing. After 75 minutes of hardening, the beam appears. One more round of planing and the beam is sent to the sawmill, where it will be shaped to match the customer’s needs.

Architects, designers, and even wholesalers visit our hall regularly – and so should you. You will get to take in the aroma of planed wood, see the gentle mist falling from the ceiling sprinklers, and touch the perfectly smooth surface of an SST beam.

You will get a first-hand look at the precision machinery and meticulous craftsmanship behind the quality beams destined to support your grand designs, whether visibly or discretely.